Robotics PhD Project

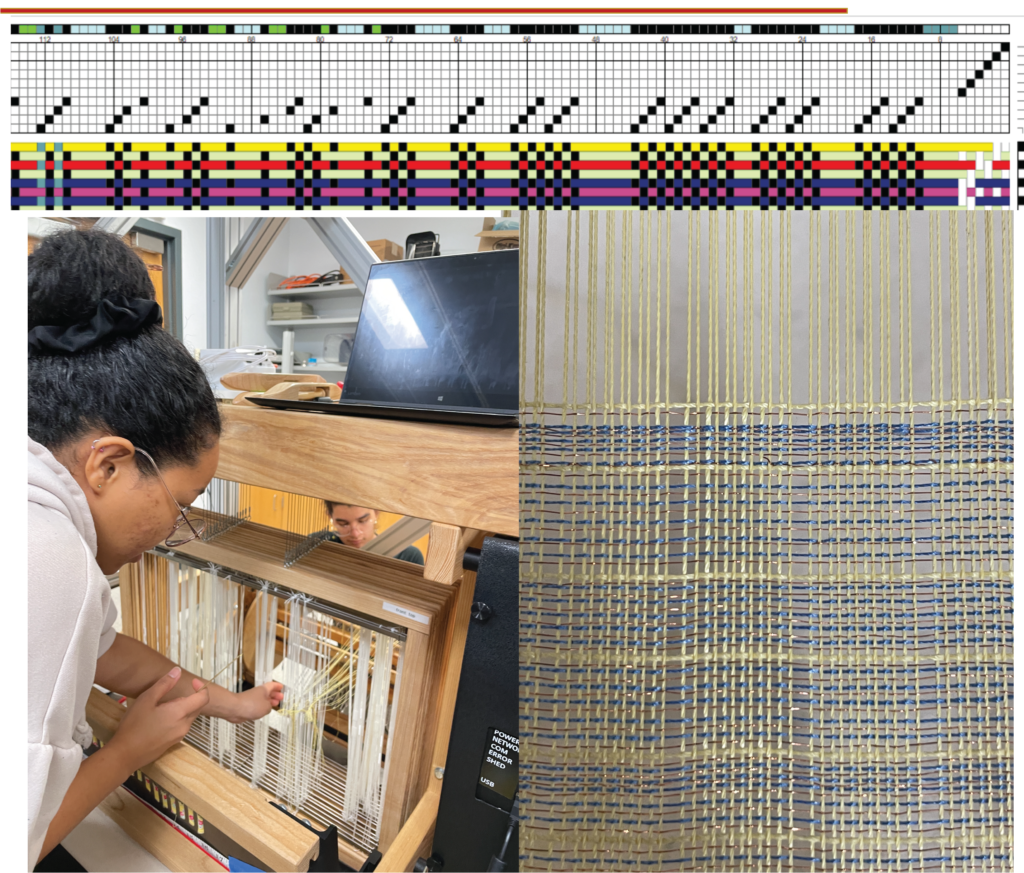

We have a Fall 2025 opportunity for a Ph.D. student at the University of Louisville in the area of fabric with embedded sensors and actuators for soft robotics. Students with Masters degrees in electrical engineering, mechanical engineering, textile engineering and natural sciences (physics/chemistry) are sought. This is an experimental project. It involves computer programming, modeling, and design work, but the main focus is hands-on lab work and data collection. This means the PhD student needs to be local during the entire degree program and carry out lab work in person. If you are interested and able to meet these requirements, go to our Join the Lab page for more details.